Willow Woody Biomass

Projects

Shrub willow has numerous environmental applications due to its unique characteristics.

Commercialization of Shrub Willow

Since 1986, the primary objective of the Willow Program at SUNY ESF has been the development of shrub willow crops for commercial biomass production and alternative applications. Research and development has encompassed all aspects of the crop including:

- Plant breeding, selection and yields

- Site preparation, planting density and best practices

- Harvesting and transportation logistics

- Environmental benefits and applications

- Bioremediation potential

- Economic modeling and analysis

- Feedstock potential supply and availability

Work is ongoing in a majority of these project areas and several highlights are provided below. There are currently about 1200 acres of commercial willow crops growing in New York State and more are likely to be added in the near future. These commercial endeavors are happening with support of USDA BCAP and NEWBio. Alternative applications for bioremediation and living snow fences are also being deployed across New York and the Northeast. Research and development of shrub willow crops has been supported by numerous funding agencies over the years including United States Department of Agriculture (USDA), United States Department of Energy (USDOE), New York State Energy Research and Development Agency (NYSERDA), Empire State Development Division of Science Technology & Innovation (NYSTAR), and the New York State Department of Transportation (NYSDOT).

Willow Harvesting and Logistics

For willow and other woody crops, harvesting accounts for about one third of the delivered cost and fossil fuel inputs. Optimizing harvesting systems is critical to improving the economic efficiency and environmental aspects of willow such as net energy ratio and greenhouse gas emissions. Case New Holland (CNH), in partnership with SUNY ESF since 2008, has developed and tested an efficient harvesting system for willow crops. The harvesting system consists of a specialized cutting header (model 130 FB) that can be equipped to any CNH 9000 series forage harvesters without any modifications to the harvester. The harvesting system is now commercially available for purchase from CNH, or rental through the NEWBio equipment access program.

Video of CNH Willow Harvester

Research, development and testing of this harvesting platform has been supported by the US DOE and NYSERDA, and has successfully achieved the following objectives:

- Develop and test a single-pass cut-and-chip harvesting system that can be used in a range of willow and hybrid poplar systems.

- Develop and refine handling systems that will efficiently move wood chips produced with the harvester from the field to the end-user.

- Evaluate wood quality characteristics of harvested chips.

- Evaluate the impact of harvesting improvements on the economics of shrub willow crops.

Biomass Yield Trials

Willow and other short rotation woody crops (SWRC) can be produced and harvested sustainably to provide substantial amounts of biomass energy for heat, power and alternative markets. Willow has several characteristics that make it an ideal feedstock for bioenergy and bioproducts:

- High yields in a short harvest rotation (three to four years)

- Ease of propagation from dormant stem cuttings

- A broad genetic base (hundreds of species world-wide)

- Ease of breeding for a variety of characteristics

- Ability to resprout after multiple harvests

- Wood chip quality similar to hardwood forest residue chips

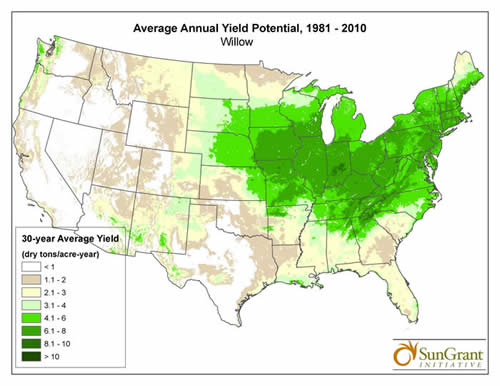

Numerous yield trials have now been planted across the U.S. and Canada. Each trial tests numerous elite cultivars developed through willow breeding programs at SUNY ESF and Cornell University. Long term data from these trials is now providing reliable estimates of biomass yield potential across a range of soil types, climates and other environmental variables. The best performing cultivars can then be deployed in commercial plantings with high confidence in consistent yield, pest resistance and performance in various site conditions. Data from these trials is also being modeled along with climate variables to predict potential yields across the U.S.

Environmental Sustainability

Sustainability has been a focus and overarching goal of the Willow Biomass Program at SUNY ESF since its inception. Shrub willow systems have the potential to provide numerous environmental and social benefits while fostering sustainable rural development. Willow biomass is a source of local renewable energy that can revitalize idle or marginal farmland and stimulate rural economies. The environmental benefits of willow include:

- Carbon neutral life cycle creates no new greenhouse gas emissions

- High net energy ratio compared to other forms of renewable energy

- Locally produced and consumed energy can offset fossil fuel imports

- Supports bird and wildlife habitat and biodiversity

- Can mitigate soil erosion and water pollution

- Can be used for bioremediation of former industrial sites

- And many more!

Research on the environmental benefits of shrub willow is ongoing at SUNY ESF including multi-criteria analysis and life cycle analysis of willow crop systems, carbon sequestration, water quality, soil properties and conservation, bioremediation and the development of best practices for all phases of the willow production system.

Bioremediation

Shrub willow can be an ideal plant choice for a broad range of bioremediation and ecological engineering projects. The shrub willow plant possesses numerous agronomical, physiological and ecological traits that can facilitate different functions in the landscape such as water filtration, extraction and degradation of harmful substances, stabilization of soils and remediation of degraded sites.

One of the primary project sites that willow is being applied to is the Solvay settling basins in Camillus, NY. Over 100 acres of willow planted on this site is serving as an effective vegetated landfill cap and closure system. The roots of the willow plants stabilize the soil on the site and control the flow of water through the ground. This prevents salts and sediments from washing off the site and entering the local watershed, protecting water quality and wildlife habitat. At the same time, the system is producing willow biomass that can be harvested for renewable energy without any substantial loss in remediation benefits or wood quality. Research on this project is ongoing and more willow vegetative covers will likely be deployed in the near future. Other bioremediation applications of shrub willow include treatment of municipal and agricultrual organic wastes, and mitigation of point-source pollution.

Alternative Applications

In addition to biomass production for bioenergy and bioproducts, shrub willow has many alternative applications that can produce numerous environmental, economic and social benefits. Some of these alternative applications include:

- Living snow fences

- Windbreaks and hedgerows

- Noise, visual and odor screens

- Privacy fences

- Vegetated buffers

- Streambank stabilization

- Ornamentals and living art

Many of the unique plant characteristics that make shrub willow ideal for biomass production also benefit these alternative applications. These characteristics include rapid growth rate, tolerance of high planting density, coppice ability, tolerance for a range of sites and environmental conditions, and low incidence of major pests and diseases. Many of these applications have already been tested and deployed in the landscape, and current efforts are focused on technology transfer and applied research.

Economic Efficiency and Analysis

Economic viability is essential to the success of any crop or industry. The Willow Program at SUNY ESF has conducted in-depth financial analysis of willow biomass crops since 2008 with the original release of the "EcoWillow" cash flow model. This model has recently been updated to version 2.0, incorporating the latest data from both research trials and commercial willow operations in New York State. EcoWillow 2.0 is a comprehensive life cycle model of the entire willow crop production system from planting through harvest and transport over seven crop rotations. Furthermore, ESF is continuing to collect data on willow harvesting, planting and other field operations and incorporating this data into EcoWillow to develop best practices, and maximize efficiencies and returns on investment. Crop production scenarios modeled using EcoWillow and other tools are also informing policy decisions for the creation of incentive programs to increase adoption of willow crops and catalyze and innovation.

Extension and Outreach

Extension services are a critical and ongoing component to the commercialization of shrub willow for biomass, bioproducts and alternative applications. Staff at SUNY ESF and the NEWBio project are providing educational and technical services to current and potential crop producers, end-users and other stakeholders. Some of the activities and services provided by the willow extension team include:

- Stakeholder meetings, trainings and networking events

- Outreach events and crop demonstration sites

- Analytical tools, crop monitoring and technical assistance

- Informational materials on crop production and management

- Newsletters, web and social media presence

- Equipment access programs, health and safety

- Small business and supply chain development

Woody Biomass Supply Assessments

In order to determine potential applications for woody biomass from New York's forests and bioenergy crops, it is important to understand the scale and spatial distribution of the woody biomass across the state. There are 15.8 million acres of forest land producing or capable of producing woody biomass outside of restricted areas in the Catskills and Adirondacks. The objective of forest biomass analysis is to estimate the sustainable level of woody biomass that could be harvested from NY forests on an annual basis as a feedstock for the production of biofuels.

Results from recent studies by the Willow Project at SUNY ESF indicate that across the state between, 4.8 and 6.4 million dry tons of woody biomass is available from forests for biofuels or other applications on an annual basis. This material is in addition to current harvesting levels for traditional forest products. Hardwoods make up the majority of the material, accounting for about 70% of the total. In order to make effective use of this supply of woody biomass there are a number of issues that need to be addressed including the deteriorating condition of traditional timber harvesting businesses, the fact that many wood energy harvests are supported by saw timber harvests, the impact of local government ordinances on biomass harvesting, the need to implement and monitor the use of best management practices (BMPs) on a site-by-site basis, and the differing management objectives of the more than 500,000 private forestland landowners who own 85% of the state’s forests. As these issues are addressed, woody biomass from New York's forest for the production of biofuels has the potential to provide markets for low value material, improve forest management, and support the development of new industries in the state that can compliment and integrate with short rotation woody crops such as shrub willow.