Sustainability at ESF

Energy & Climate

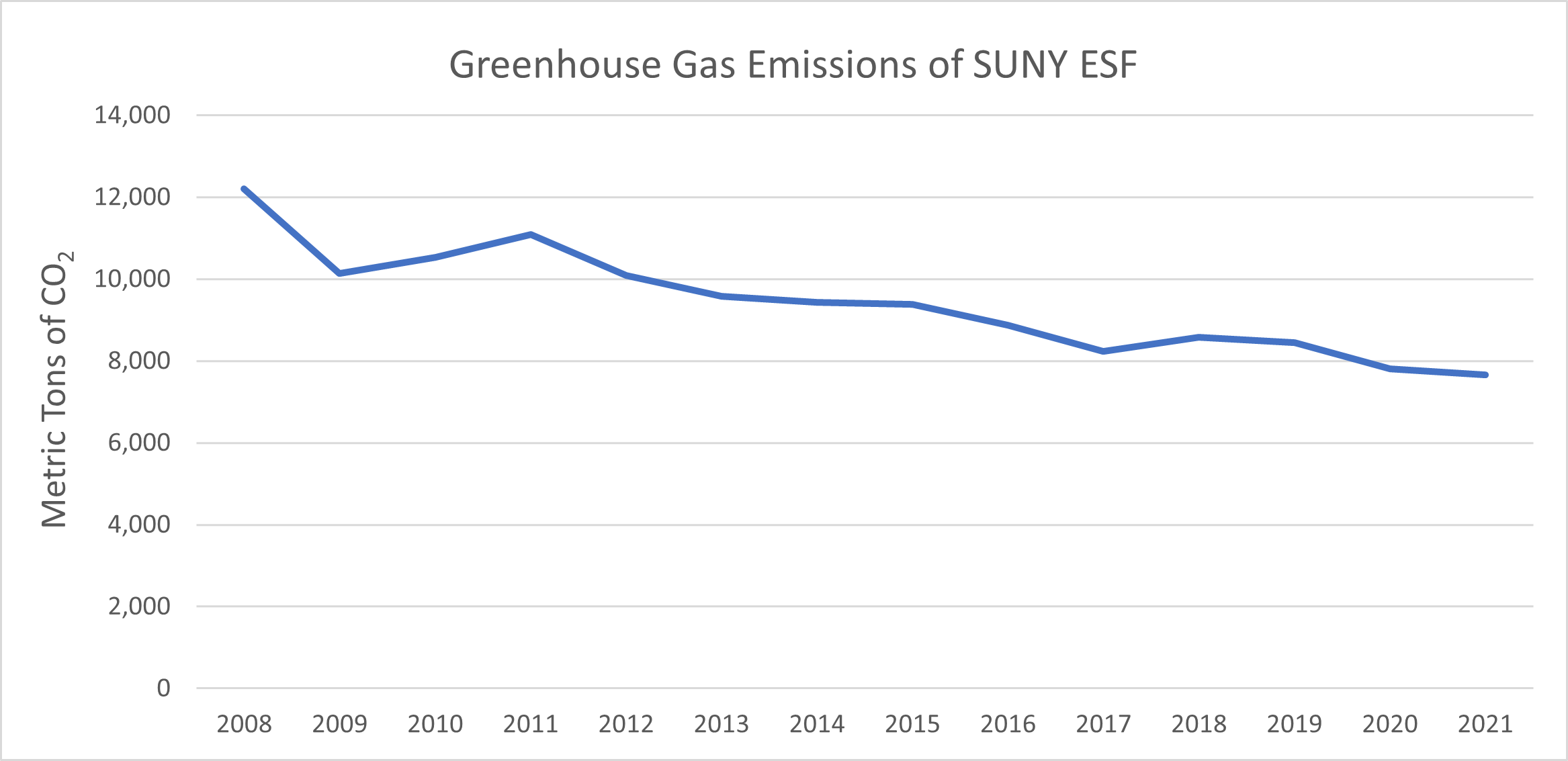

In 2007, former ESF President Neil Murphy made ESF a charter signatory of the American College and Universities President's Climate Commitment (ACUPCC), now Second Nature. This action committed ESF to becoming a carbon neutral campus by reducing emissions to the maximum extent possible and offsetting remaining emissions to achieve net zero greenhouse gas (GHG) emissions. Since that time, ESF has been actively making improvements to the Syracuse campus and regional properties to reduce energy use, transition to renewable energy sources, and lower greenhouse gas (GHG) emissions.

In 2021, ESF completed the College's first Clean Energy Master Plan in partnership with Ramboll, with funding support from the NYSERDA Reforming the Energy Vision (REV) Campus Challenge. The plan provides a snapshot of historical energy and GHG trends, and a roadmap for further reductions in energy use, fossil fuel dependence, utility costs, and GHGs.

For more detailed real-time and historical energy usage on campus visit our Mighty Oaks Energy Dashboard!

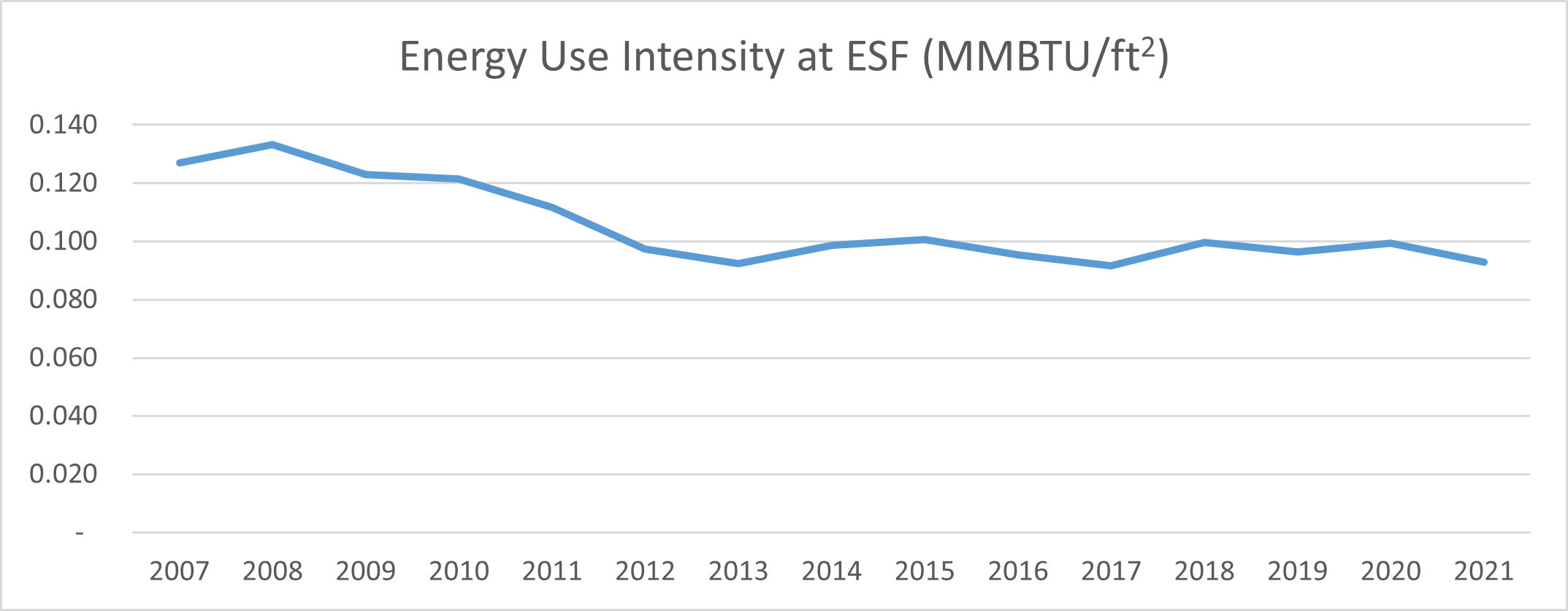

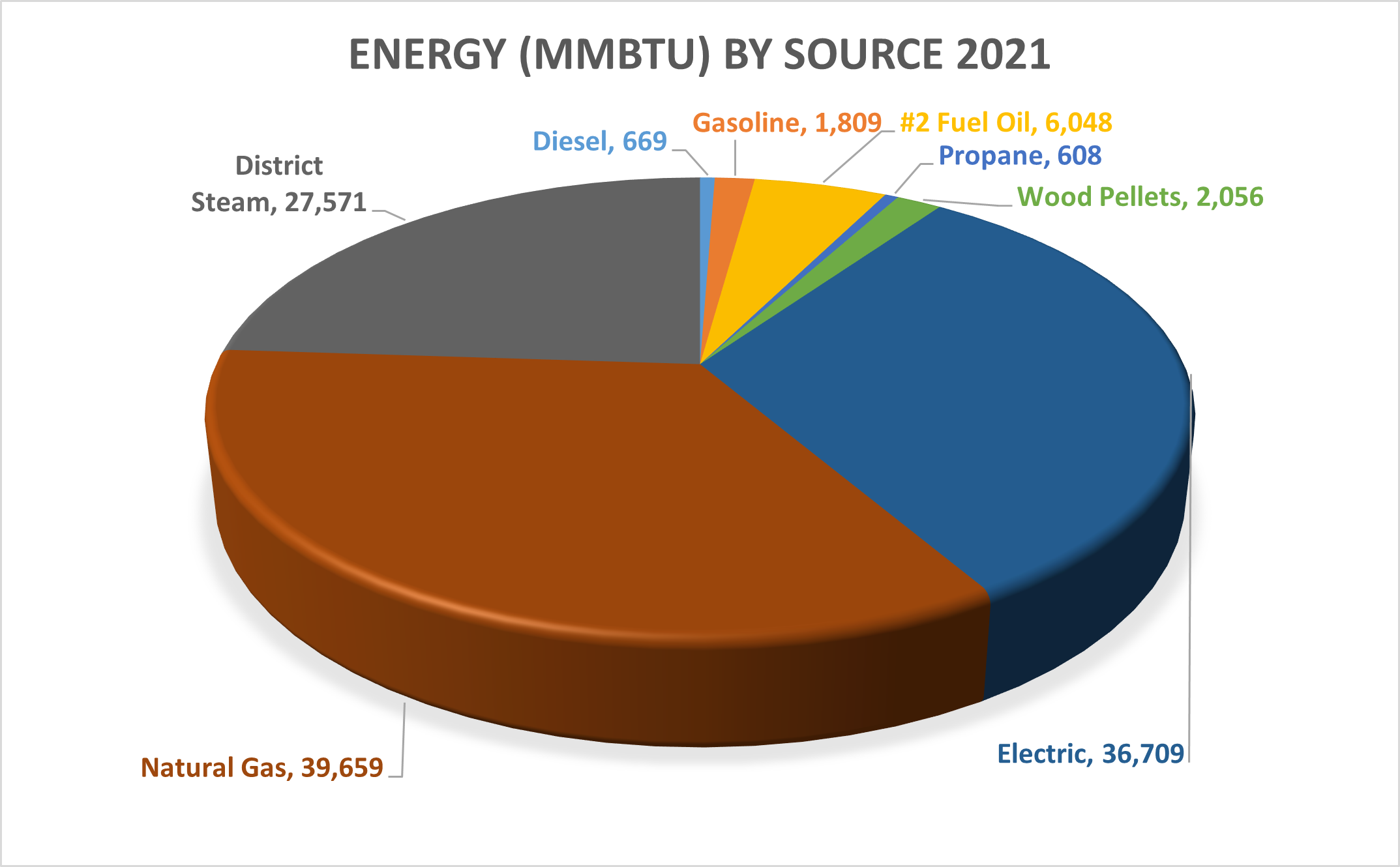

Over the past 15 years, ESF has reduced the energy used per square foot on campus. Our biggest energy sources are gas, electricity, and steam.

Campus features several different forms of energy generation. Electricity is produced by our from our photovoltaic (PV) solar panels and natural gas microturbines. Steam is generated from combusting biomass or natural gas or by capturing waste heat from the microturbines.

ESF has five solar PV arrays. Roof-mounted systems can be found on Walters Hall, Moon Library, and the Adirondack Ecological Center. A building-mounted (southern exposure) system is located on Baker Lab and a ground-mounted system is installed at the Tully Experiment Station. In total, the five systems produce about 75,000 kWh of electricity each year. More detailed information can be found on our Solar project page.

The Gateway Center is a LEED Platinum building designed to produce more energy than it consumes. Our CHP (Combined Heat & Power) plant, located on the lower level of the Gateway Center, provides heat and electricity to Gateway and several adjacent buildings. Visit the Combined Heat and Power project page for more information about this system.

ESF has installed over 8,000 LED tubes at its Syracuse and Regional campuses. This results in approximately $30,000 in annual utility savings and a reduction in electricity usage of 438,000 kWh/year. This is equivalent to removing 67 cars from the road each year!

The biggest energy users in a building are the fans and pumps associated with the HVAC systems used for heating and cooling. ESF has installed Variable Speed Drives (VSD) on the majority of campus equipment. This allows the motors to fluctuate their speed based on demand. Before the installation of the VSD, the equipment was either off or on, running at 100%. These VSDs save energy and increase equipment lifespan.

Over the past 15 years, the College has successfully decreased our carbon emissions by over 30%! ESF is committed to a comprehensive approach to mitigating the College's carbon footprint. Projects include energy conservation and efficiency, green building construction and renovation, building controls, clean energy systems, virtual power purchase agreements, electrification, and deep decarbonization. We are also studying the carbon sequestration of our forests.

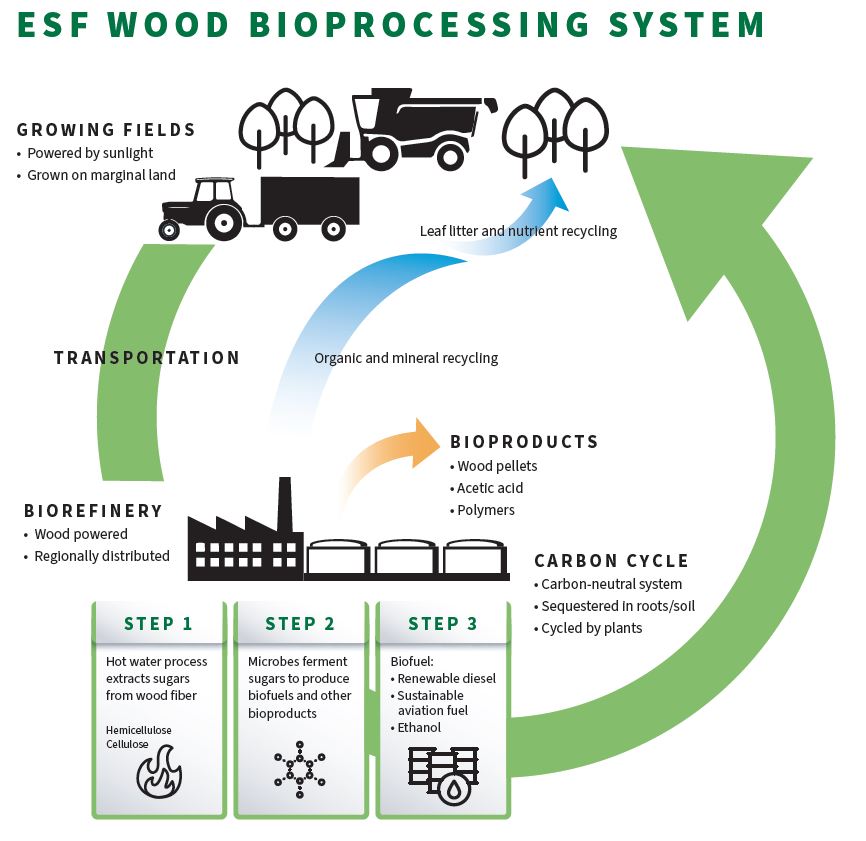

ESF is actively working with numerous university, private, and public partners to research and develop shrub willow for renewable energy and environmental applications. Willow systems can be multifunctional and produce sustainable energy along with other value-added benefits to ecosystems and communities.

Download a high level overview of our Willow Biomass research and visit the Willow project homepage for more in-depth reading.